July 7, 2017

Customer Profile: Amerikohl Mining, Inc.

Amerikohl Mining, Inc., is made up of three divisions: Amerikohl Aggregates, Amerikohl Transport, and Patriot Exploration, which develops and produces natural gas wells.

They are one of the top surface mining coal producers in Pennsylvania, producing nearly 1,000,000 tons of coal annually. Amerikohl Aggregates produces in excess of 1.5 million tons per year of premium State Approved Limestone products from two active quarry sites. Their limestone is utilized in the construction of roads, bridges, gas drilling platforms, water, sewer lines, railroads (ballast) anti-skid and many other local infrastructure projects. They have more than 150 customers in in Western Pennsylvania, and more than 130 employees working on projects from heavy highway construction, erosion and sediment control and more.

Problem

Prior to discovering Stockpile Reports, Amerikohl relied on belt scales to measure their inventory and productions levels. However, the scales were notoriously inaccurate, and changes in moisture, precipitation and other factors gave a wide margin of error. They would try to quantify yardage moved with a laser rangefinder measurement, which was also unwieldy and did not produce consistently accurate results. This occasionally resulted in Amerikohl running out of inventory during busy summer months, as their recorded numbers did not match what was actually on the ground. They also tried new methods of measurement, including using their own drone and mapping software, but it was very time intensive. They were often guessing as to efficiencies in expensive operations such as heavy machinery output. Luckily, they heard about Stockpile Reports through the Pennsylvania Aggregate and Concrete Association.

Solution

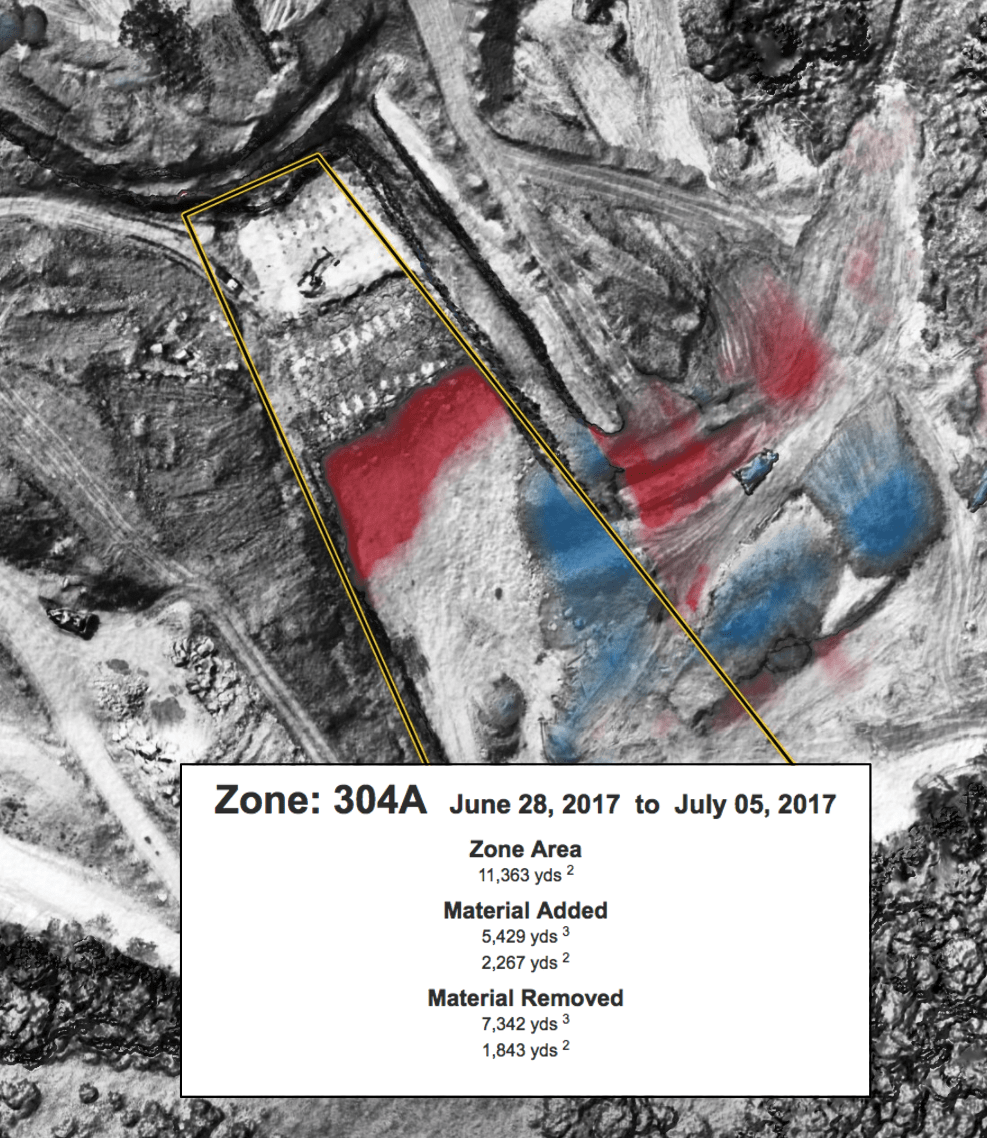

Amerikohl moved to inventory management and Progress Reports with Stockpile Reports. They schedule weekly drone flights through their portal and have accurate, weekly reports that they use to drive their operations. Initial drone flights set up a baseline, creating an accurate 3D modeled site. Subsequent flights update the model and record changes in shape and volume. By monitoring and measuring exactly the amount of material that is produced, moved and removed from their site, they can determine how much is being produced in what period of time – this allows them to sell stone to customers that hasn’t even been uncovered yet, as they have confidence in production levels.

As another benefit, Amerikohl can track the efficiency of their bulldozer operators. “Now we know how efficiently our equipment is at moving material. One of our big bulldozers, costs more than $300 an hour to run. We know how much it should move in a shift – if we don’t, it’s big bucks,” said Stilley. They can even see which drivers are more efficient at operating the machinery, moving the material in the shortest period of time. They would also be able to see if there was a delivery that was not recorded in the books, or other anomalous event. All of these factors go right to the bottom line of Amerikohl.

Progress Reports is also important for safety reasons. They can see how the road surface over or between stockpiles is changing over time, and if a quarry with steep cliffs is deteriorating or in danger of collapse.

“We have 6 people on our team who have visibility into the reports. We can all jump on a weekly call and plan the week. We love the aerial photos too – knowing we know exactly what and how much is on the ground.” – Jamie Stilley

Specific benefits:

- Automatic weekly drone flights

- Elimination of “backend” software calculations

- Accurate assessment of driver and equipment efficiency

- Great reduction in time/cost of measurement

- Accurate measurement of production increases sales

- Clear reports for financial/accounting statements

Conclusion

With Stockpile Reports, Amerikohl has 100% visibility into its sites on a weekly basis – something that was not possible with outdated belt scales or cumbersome measurement techniques. Our Progress Reports Service with its easy to read reports lets them quickly see any safety issues or production issue that could interfere with their business. Now they can “set it and forget it” knowing that weekly drone flights, with clear images and accurate site modeling keep them ahead of their competition. They can also maximize profitability by keeping drivers and equipment operating at peak efficiency, keeping costs down. This lets them keep doing what they do best – serving their customers in Western Pennsylvania.

Stay In the Know

Be the first to know about the latest Stockpile Reports news and features.