February 8, 2016

On the Floor at World of Concrete 2016

World of Concrete 2015 attracted more than 55,000 professional registrants and showcased just over 1,400 leading suppliers.

Nearly 56,000 construction pros were pre-registered for the 2016 event, with almost 1,500 exhibitors filling more than 675,000 sq. ft. of exhibit space. At the final tally, there were almost 60,000 attendees to the Las Vegas Convention Center.

World of Concrete is the only international trades show dedicated to the commercial concrete and masonry industries in 2016. It featured innovations and expert know-how from more exhibitors than the 2015 edition of the event. The show floor was close to 750,000 net square feet, the largest in seven years.

There were many people in attendance from other countries, with the largest contingent traveling in from Canada, as well as a strong showing from South America.

This year was Stockpile Reports’ first exhibition in Las Vegas, and we can attest that the attendance was strong. We had hundreds of visitors to our booth during the week. Stockpile Reports formally announced our bin and bunker measurement capability via either an iPhone or drone Tuesday morning, immediately after the show opened, with a press announcement and press conference.

The Stockpile Reports team welcomed the opportunity to meet new, and current clients at the show. There were also many networking events after the exhibition halls closed at 5PM.

We look forward attending and exhibiting again at World of Concrete 2017, from January 17-20 at the Las Vegas Convention Center. Our team will be wearing big smiles and comfortable shoes!

Stockpile Reports arrives in Las Vegas!

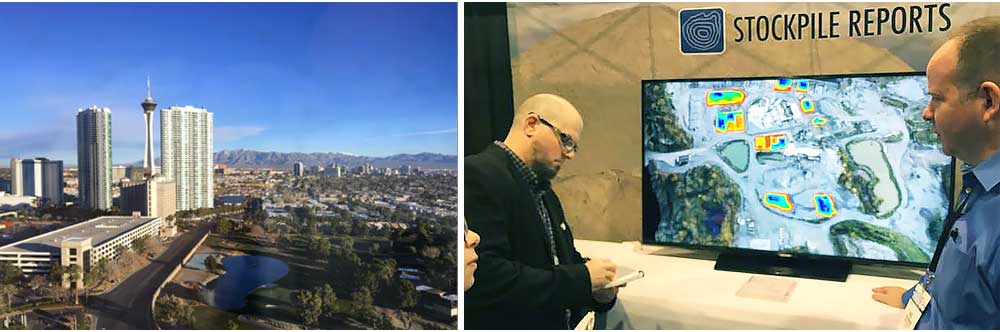

The World of Concrete Show opens with blue skies and a Press Conference.

David Boardman, CEO talks about bunker measurements using a drone. Meanwhile, attendees were also visiting outside exhibits.

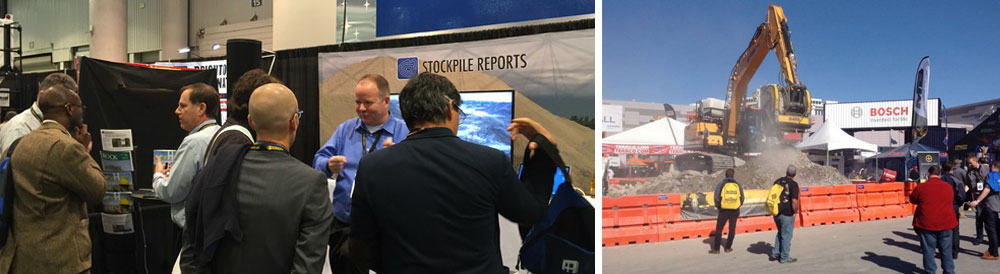

The team is glad to sit down after a busy day at the booth.

Almost 60,000 attendees came to Las Vegas for the event.

We decided to model the Elvis statue in the lobby at the Westgate Hotel in 3D using our iPhone.

Reviewing upcoming events and new opportunities for 2016 helps us think about creative marketing solutions.

After the show there were many opportunities to make new connections.

Stay In the Know

Be the first to know about the latest Stockpile Reports news and features.