March 25, 2019

The Dirty Secrets of Stockpile Inventory Management – Part One

A Two-Part Series on What Stockpile Measurement Services Are Not Telling You

Drone companies are announcing new hardware advancements on a monthly basis with technical terms such as RTK, PPK, Megapixel, etc. All of these advancements promise improved absolute point cloud accuracy at an increasingly smaller fraction of a foot. Our clients are constantly asking if they should upgrade to the latest drone. While the new drone hardware will measure more precise surface data, no one talks about a set of two factors that can easily erase any accuracy claims on stockpile measurements. In this two-part series, we are going to deep dive into the two major factors that can derail any stockpile inventory management program.

Part 1: Garbage In, Garbage Out

A common term used in data analysis is “garbage in, garbage out”. This is the premise that feeding software poor data will net poor results. This premise also applies when measuring a stockpile using any modern measurement device. Poorly managed stockpile conditions are the equivalent of “garbage data” which potentially leads to poor measurement results.

What are poorly managed stockpile conditions? Most commonly these conditions are stockpiles with vegetation growing on the surface and around the base, commingled piles, standing water at the pile base, etc. Measurement data risk is introduced due to unknown surface shape and pile toe elevations where the stockpile is obscured from the camera. Measurement professionals make estimations of the true stockpile surface shape and ground elevations to minimize the possible impact of “garbage data” fed into volumetric analysis software. However, even the best surveyor can only make estimations of the true stockpile surface and toe. Occasionally incorrect estimations derail a measurement which affects the bottom line of companies. Stockpile measurement companies do not want you to know this.

Standing water obscures the ground elevation of a stockpile.

At Stockpile Reports, we teach our clients that the first step to creating a successful stockpile management program is to clean up their stockpiles. The number one way to increase the accuracy and consistency of measurements is to proactively clean up stockpile conditions (removing the garbage from your data). We did an analysis of our data and discovered one out of five piles measured in 2018 had an environment risk issue. This is a real problem that every company has to face.

One out of five stockpiles measured in 2018 had a environment risk issue.

We have built sophisticated backend data modeling techniques to correct the areas of stockpiles where pile management risks are present. However, an incorrect stockpile surface or toe modeling assumption has the potential of reporting a volume up to 20% off the true value.

This is the core reason we tell clients to clean up their sites before spending any additional resources on new hardware. A one percent improvement in surface accuracy with survey grade drones can easily be erased by an incorrect measurement of a stockpile with vegetation growing over it. Think twice before spending resources on hardware. Focus on your pile conditions first.

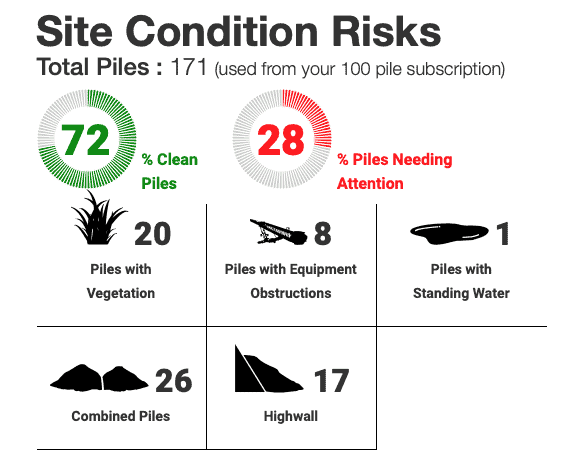

Stockpile Reports Helps Manage Measurement Risks

We provide a top-level report of the total number of your stockpiles that have management issues. This helps area managers proactively mitigate risk.

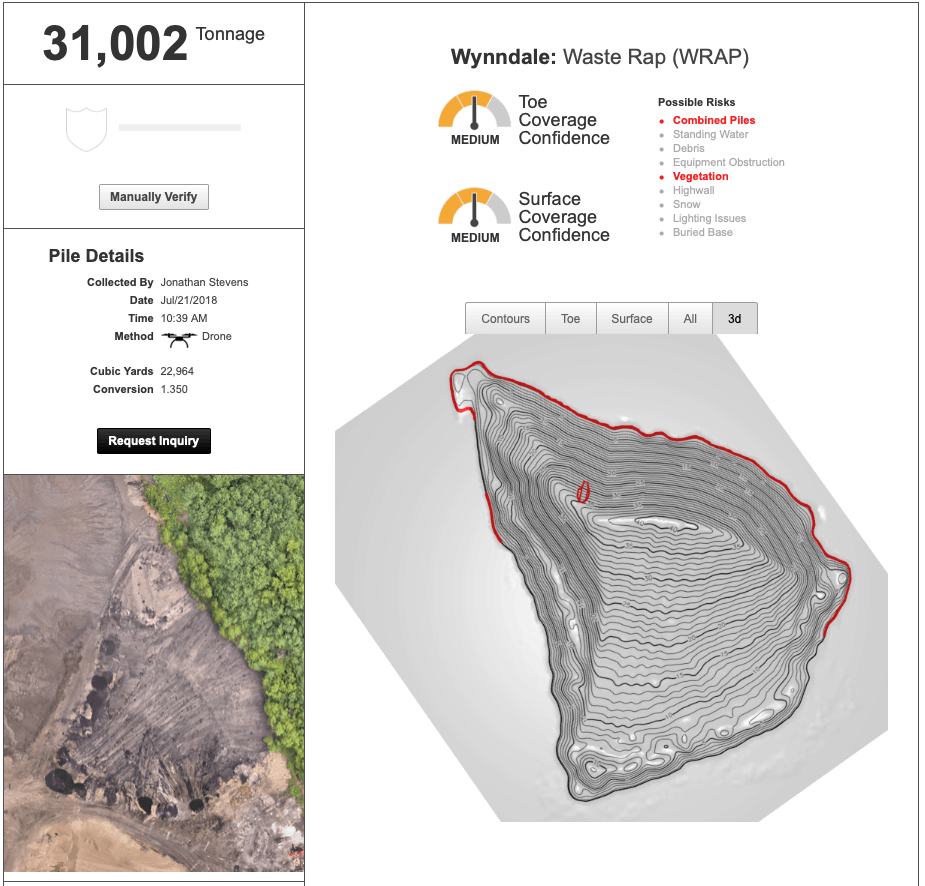

Not knowing which stockpiles have poorly managed conditions is a common issue for companies with inventory spread over a large geographic area. Stockpile Reports does the work for you and reports the number of piles at your company that have risks of measurement issues. Each individual stockpile measurement report breaks down how much of the surface and toe is visible to the measurement device. Any issues such as vegetation, snow, or standing water is also highlighted on the report. This arms operations managers with the data to ensure their sites are being proactively managed for the best measurement data possible.

Stockpile measurement reports from Stockpile Reports highlight any potential management issues contributing to an accuracy risk. The red line around the base is where the drone did not see the stockpile’s toe due to vegetation and an adjacent pile pushed into the main pile.

Common Measurement Risks

We have reviewed thousands of stockpile measurements from 2018 and determined that a handful of common management issues have the largest potential for incorrect results. Fortunately, all of these issues can be eliminated by investing in site preparation prior to measurement. Below are the four common issues, how they impact your measurements, and how to correct the issue:

Commingled Stockpiles – Stockpiles that are pushed against each other often lead to an ambiguous area where the different materials split. Often, a site-level manager will make a best guess at where the split occurs by reviewing an aerial photo. This leads to uncertainty as to where the true stockpiles split. Not until one of the stockpiles has been completely consumed, do we know if the pile was properly split. Correcting commingled piles can be addressed in two ways. The first option is to physically separate each stockpile and create a clearly visible toe around each material. The second option is to temporarily separate the two materials and build a separation wall to clearly delineate where the stockpiles split.

The pile in the center of the image is combined with a second pile. Vegetation is also obscuring the surface and toe of the pile.

Standing Water – Fall and winter bring drastic weather to stockpile locations. A heavy rain event can cause water to pool up to several feet around stockpiles. Even the best drone cameras on the market cannot see through the murky, pooled up water. Water levels just several inches above the toe of a stockpile will shorten the total height of a stockpile measurement. While a couple inches of water may not seem like a big issue, measurements of stockpiles with large footprints can be short by hundreds or thousands of tons depending on the depth of the water. You can fix this issue by ensuring your site is graded to allow water to flow away from stockpiles. No one wants a downpour the night before a critical month end inventory to ruin the accuracy of the measurements.

Overgrown Vegetation – camera drones are great tools for measuring stockpiles. However, they can’t measure what they don’t see. Piles covered by tall grass or shrubs will inevitably increase the volume of a stockpile measurement. Vegetation around the bottom of a stockpile can obscure the true ground elevation. Estimating the ground level can lead to inaccurate results if done incorrectly. Thankfully there is a simple fix for this issue. \Have your maintenance crew cut down any built-up vegetation a day or two before your stockpile measurements. As a side benefit, your product will stay clean for sales.

Move Piles Away from Highwall – Occasionally we see stockpiles pushed up against large banks or highwalls. The ground underneath these stockpiles have ambiguous slopes and dips. Clients will claim a wall will have a grade of X% or provide a survey model of the bare ground. Usually, these ground references do not match what is seen by the drone. This is mainly due to the fact that the ground behind a pile on a highwall has most likely changed over the years and the last survey was done far in the past. Don’t take the risk, move your stockpiles away from highwalls prior to measurement.

This stockpile is pushed up against a sloping road creating an ambiguous pile toe and ground level. We suggest moving the pile off the slope.

Great Data In, Great Data Out

Armed with the stockpile conditions reporting tools from Stockpile Reports, you can ensure all of your measurement data is high quality leading to precise volume reports. We recommend cleaning up your inventory as often as possible to ensure you are not at risk of an accidental write off. In part 2 of this series, we talk about the post-measurement data interpretation factors that can still derail a well-intentioned stockpile measurement program. However, every great inventory program starts with ensuring you capture quality data from the beginning.

Stay In the Know

Be the first to know about the latest Stockpile Reports news and features.