April 23, 2019

State of Texas Ranked #1 in Stockpile Reports Most Digitized Building Material Industries

The ready mix, aggregates, asphalt, and transportation industries in Texas are leading the country in their advancement of technology.

With an exploding population and the growth of high tech companies, it is no surprise Texas leads in innovation. We researched digitization efforts across the country and Texas clearly came out on top. This is why we are proud to announce the Texas building material industry as the leader in innovation. Interested in who we determined as the top 5?

Here they are:

- Texas

- Illinois

- Montana

- Washington

- Colorado

Criteria

How did we derive our ranking results? Below are the criteria we used.

- We performed an extensive search of articles and customer success stories from companies in the industry using new techniques to digitize their current processes and operations in building materials production and utilization.

- Discussions with people at several association events and tradeshows to get a pulse on innovation in the industry.

- We reviewed our own data and looked at which states were measuring inventory with drones or iPhone, an indicator that the state is adopting more advanced material measurement techniques beyond the walking wheel and traditional GPS methods.

Companies Going Digital

The building material industry is going digital in a big way. A clear indicator that has stood out in the past couple years has been Cemex leading the charge by releasing a full set of applications to increase plant uptime, reduce workplace injuries, and improve communication with suppliers. Lehigh Hanson has also demonstrated leadership by implementing remote monitoring and support of cement plants as well as building new software to optimize production. TxDOT has also been at the forefront of digital innovation for all DOTs. Their list of ongoing programs to digitize road construction, safety, and information is extensive.

Texas is Growing in a Big Way

Historically, Texas has been a center of technological innovation. Houston has been a central hub of the aerospace industry and continues to be today. The semiconductor industry had a large start in Texas at Texas Instruments Inc. and later Dell computers were founded in Texas. Today, Forbes’ says Austin and Dallas are predicted to be the next Silicon Valley. No surprise with universities such as Texas Tech and Rice producing highly skilled engineers and computer science graduates.

Texas is also not a stranger to some of the largest construction projects in the nation. Globe Life Field, the new home of the Texas Rangers, will cost $1.1 billion dollars and will require massive amounts of concrete to build. Texas is also home to several large oil pipelines and refining projects as well as massive highway expansion projects in the major urban areas. According to many population studies, Texas is predicted to be the second-fastest-growing state in the Union by the proportion of the population and the number one state in growth based on the absolute population. Predictions also place Austin, TX as the third fastest-growing city in the United States through 2035. This means more homes, office buildings, retail centers, factories, etc. More vehicles on the roads also mean a greater need for highway building and maintaining.

One common thread through all this growth is that it will require concrete, aggregates, and asphalt. These are the foundational ingredients for construction. The whole industry is growing to meet the need for building material. However, setting up a new ready mix plant, aggregates quarry, or asphalt production facility takes time. Growing a road maintenance fleet doesn’t happen overnight and requires a large amount of capital investment and personnel recruitment. Texas’ rapid growth is the very reason their industry is looking to digital innovation to produce more product efficiently with existing resources.

How Texas is Digitizing The Stages of Building Material Production and Utilization

Overburden Removal and Blasting

The digitization of the building materials production and utilization begins before a single speck of rock is moved. Aggregates producers are using camera-based drones and lidar systems to digitally preserve a topographical model of what their site looks like prior to overburden removal and blasting. An advantage of having a digitally preserved state of the quarry prior to overburden removal is that quarry operators are able to take subsequent captures of the quarry after overburden removal and blasting to digitally track the volume of material removed in each stage. The largest benefit is that the quarry operator knows exactly how much overburden to replace at the end of a project. Also, after each blast, the operator will be able to form an appropriate crushing plan based on the exact volume of rock blasted off a wall.

Crushing & Screening

During the crushing and screening stage of the aggregate production, advanced tracking systems such as optical belt scales report the amount of final product. The more advanced optical tracking systems are also able to visually scan the aggregate to ensure it is staying in spec mid-production. This information is seamlessly entered into production tracking software. Plant operators are no longer relying on their crews to track metrics by hand and input the values into disconnected spreadsheets.

Stockpiling Aggregate

After crushing and screening aggregate, the material is stockpiled for future use in ready-mix, asphalt, and bulk crushed rock sales. The industry is rapidly moving from a period inventory approach to a more accurate drone-based measurement system. The most progressive companies in Texas are integrating stockpile tracking software with their ERP systems giving production and finance executives near real-time inventory numbers.

Ready Mix & Asphalt Production

Aggregate, cement, and asphalt fed into the ready-mix and asphalt plants are being digitally tracked by sensor systems ensuring the mix designs are accurate. Digitally tracking the material flow from stockpiles to plants ensures inputs are being reconciled. This digital reconciliation process improves efficiency by ensuring all the managers in operations and finance have up to date snapshots of the total material available.

Logistics

Ready-mix and asphalt operators are digitally connecting their logistics systems to their material inventory. Optical systems are keeping an hourly tab on the available aggregates at ready-mix and asphalt plants. As the material begins to run out, tracking software automatically notifies the aggregates producers to ship more material to the ready-mix and asphalt plants. The live tracking system eliminates the risk of a stock-out and over-ordering materials for a rainy day.

Construction & Paving

DOTs and construction companies are also digitizing the way they do business. Materials are being digitally tracked as it arrives on site for a construction project. The DOT and construction companies are ensuring the correct amount is being delivered from their supplier. This digitization process is currently being used at the Texas Department of Transportation. They lead the way in statewide transportation innovation. With over 79,000 miles of roadway, TxDOT has more highway miles than any other DOT in the United States. Four years ago, TxDOT started tracking the flow of maintenance materials using Stockpile Report’s inventory tracking solution.

In a year-long study, they concluded they saved $2.1 million and 20 FTE’s in time by streamlining their stockpile inventory measurement process.

These savings were passed on to road building and maintenance projects.

Conclusion

Technological advancements have revolutionized many different industries over the past several decades. Texas has always been at the forefront of the technology revolution. This comes as no surprise as it is the home to some of the largest and more innovative companies on the planet. The attraction to live and work in Texas keeps growing which means a greater need to technically revolutionize the building materials industry to meet demand.

Ready Mix, aggregates, and paving companies in the state of Texas have figured out ways to track, analyze, and drive decisions using innovative technology. With continued advancements in drones, cameras, and wireless technology coupled with emerging AI, photogrammetry methods, machine learning, and cloud computing, Texas will continue to stay on top, leading the way in building material industry innovation.

About Stockpile Reports

Building material plants use Stockpile Reports to monitor their inventory levels for automated replenishment. Building material production sites use Stockpile Reports for fast, smooth, reliable physical inventory counts.

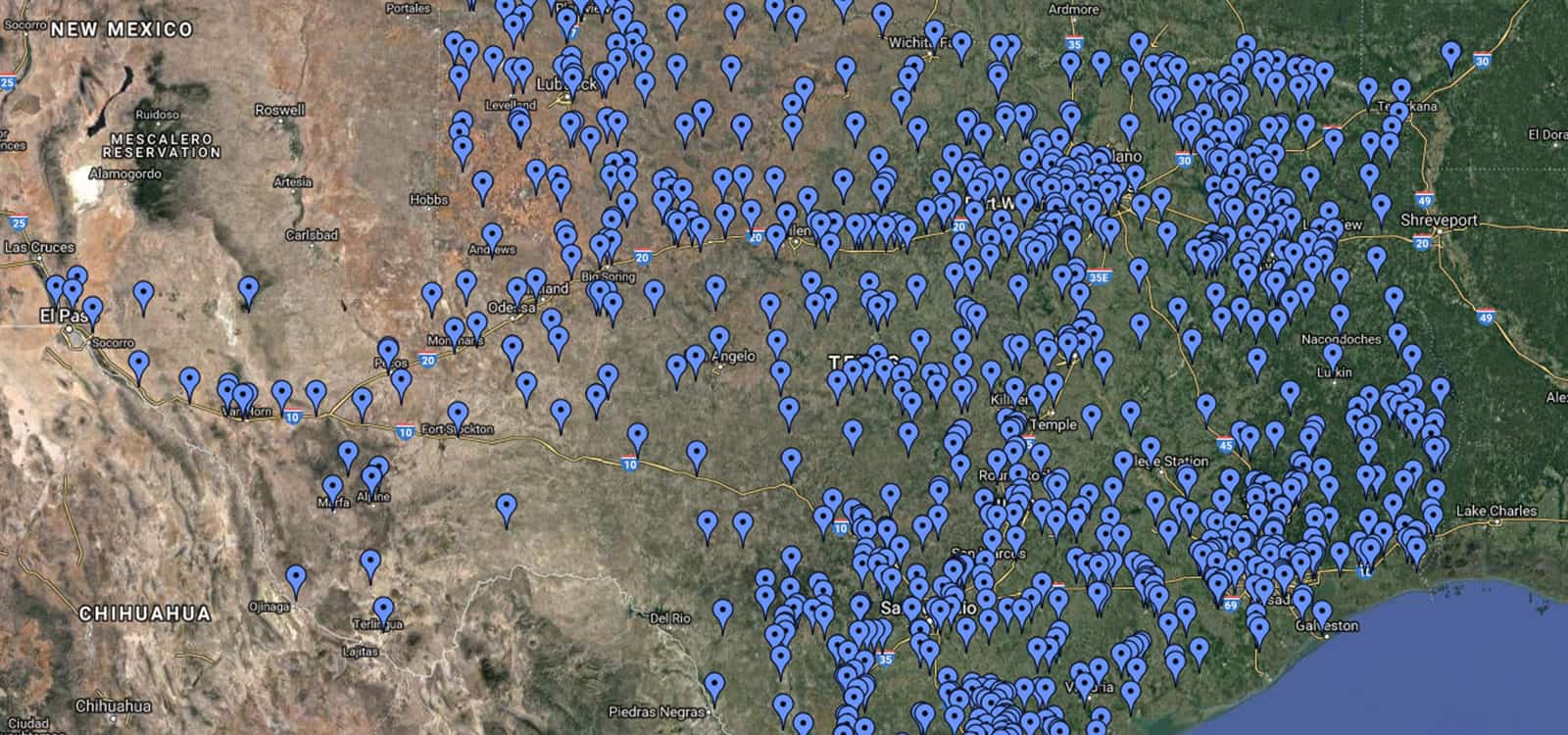

Across Texas, Stockpile Reports is utilized by 33 Companies at over 1000 locations. Industries using Stockpile Reports include ready-mix, aggregates, asphalt, DOTs, mobile crushers, cement, frac sand, brick, roofing materials, ceramics, agriculture, and material handling. Seven of the top ten aggregates producers in the United States use Stockpile Reports.

Stockpile Reports is an active member of TACA (Texas Aggregates and Concrete Association) and currently works with leading companies in the state such as the Texas DOT, Alleyton, Lehigh Hanson and CAPA Texas.

To find out more, email us at logistics@stockpilereports.com or call +1 (425) 428-5266.

Stay In the Know

Be the first to know about the latest Stockpile Reports news and features.