October 21, 2015

Aggregates Production and Physical Inventory

Rock Products recently published the news: Aggregates Production Rises in Second Quarter.

The news stated, “An estimated 607 million metric tons (Mt) of total construction aggregates was produced and shipped for consumption in the United States in the second quarter of 2015, an increase of 3 percent compared with that of the second quarter of 2014, according to the U.S. Geological Survey (USGS).”

However, further down into the article was some less-than-good news: “The estimated production for consumption of construction sand and gravel in the second quarter of 2015 decreased in five of the nine geographic divisions compared with that sold or used in the second quarter of 2014. The largest decreases in percentages were recorded in the West South Central and the Mountain divisions.”

Notice that the word used to describe both the positive and negative production measurements is “estimated”.

How many aggregates producers do you think estimate their production and sales every quarter? How many do you think were either pleasantly, or unpleasantly surprised when they recorded inventory numbers?

Aggregate Research states that the 2015 Q2 production numbers were gained by the USGS via state surveys, with the USGS Mineral Industry Surveys providing more detail.

Estimation and surprises (good and bad) are not new in the aggregates industry. Tracking the quantity of goods on hand has traditionally been difficult to do in dynamic or remote quarries and sites.

There are two types of inventory methods: a periodic inventory method, and a perpetual inventory system.

In a periodic, or physical inventory method, there is no cost of goods sold in an accounting period until there is a physical count.

Challenges with this method include:

- Estimation errors. You must estimate the cost of goods sold during interim periods, which will likely result in a significant adjustment to the actual cost of goods whenever you eventually complete a physical inventory count.

- Large adjustments. There is no way to adjust for obsolete inventory or scrap losses during interim periods, so there tends to be a significant (and expensive) adjustment for these issues when a physical inventory count is eventually completed.

If your company physically measures stockpiles weekly, monthly, quarterly, every six months, or by year, you use the periodic (or physical) inventory method. The more often you measure, and record the results, the more accurate your accounting will be.

Discrepancies or errors in accounting are difficult to investigate, if physical measurements are not completed often and accurately, as there are not enough physical inventory records to track through. Write-offs happen. Less accurate record-keeping makes it extremely difficult to set future performance expectations.

Aggregate producers assume degrees of inaccuracy in measurements (such as density variations and belt calibrations.) For enterprises with multiple sites and locations, any variation could multiply into the millions of dollars.

Walmart knows exactly what is on their shoe shelves. McDonalds knows how many Big Macs a store sells every day, and management at Target has accurate numbers as to how many candy bars are available for events such as Halloween. They know this by constant physical inventory methods.

Perpetual inventory enables site owners and businesses to obtain real-time knowledge and confidence about existing inventory on hand, if measurements are made and recorded often and regularly.

Frequent, accurate measurements provides feedback into the success of production modes, and helps Senior Management team evaluate performance. The results are highly auditable too, because there are continual updates to either the general ledger or inventory journal.

Every stockpile is cash sitting on the ground.

Survey costs, production downtime, labor costs, tool accuracy, site locations and turn-around times have been barriers to achieving a state of accurate inventory.

Isn’t it time for Aggregates producers to finally update measurement processes to enable rapid physical inventory?

Stockpile Reports is the only measurement platform enabling large enterprises to have accurate inventory. We have the lowest costs, our results are highly auditable and available in hours, giving companies the fastest accurate physical inventory measurements available. Getting those measurements performed often, regularly, and accurately is the key to inventory control.

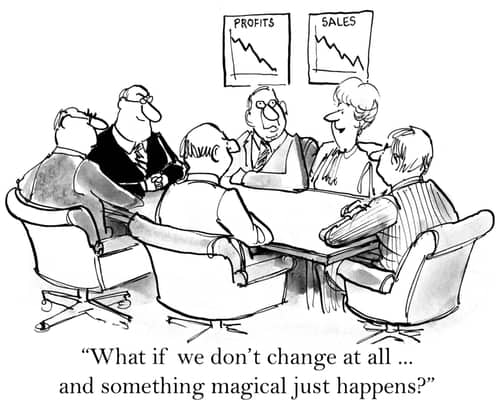

Think about it: if your inventory numbers were better, would it change your business? How would if affect decision-making?

Contact our team for more details about how we are currently solving accurate inventory problems for enterprises, and how we can help you.

*From AccountingTools.com

Stay In the Know

Be the first to know about the latest Stockpile Reports news and features.