When exploring drone-based stockpile measurement, you’ll likely hear from software vendors that Ground Control Points (GCPs) are a requirement for accurate results.

While that’s true for certain survey-grade projects, stockpile measurement is a very different use case. At Stockpile Reports, we’ve proven that GCPs aren’t necessary for reliable, precise stockpile inventories. Here’s why.

What Are Ground Control Points (GCPs)?

Ground Control Points are marked locations on the ground with known GPS coordinates. In traditional photogrammetry, GCPs act as anchor points that help align aerial imagery to the real world. They are especially important in surveying projects where absolute accuracy is required such as mapping property boundaries, construction layouts, or legal surveys. But stockpile measurement has a different accuracy requirement than those types of projects.

Stockpile Measurement Is About Relative Accuracy

For managing your inventory, you don’t need survey-grade precision down to the centimeter. What you need is consistency and reliability, which means volumes that are accurate relative to your last measurement. An accuracy range of within 2-5% is generally acceptable with financial estimates.

Whether you’re reconciling inventory at the end of the month, tracking usage over time, or validating supplier deliveries, it’s more important that each new measurement is aligned with your previous one than it is to have an absolute GPS tie to the earth. That’s why Stockpile Reports focuses on relative accuracy and precision, not survey-grade absolute positional accuracy.

This is because financial reporting values using the same, independent and objective process for all measurements. Whether you’re reconciling inventory at the end of the month, tracking usage over time, or validating supplier deliveries, consistency is king.

How We Ensure Precision: Aligned Aerials

GCPs do deliver flight-to-flight precision by anchoring each dataset to real-world points. Stockpile Reports developed a better approach.

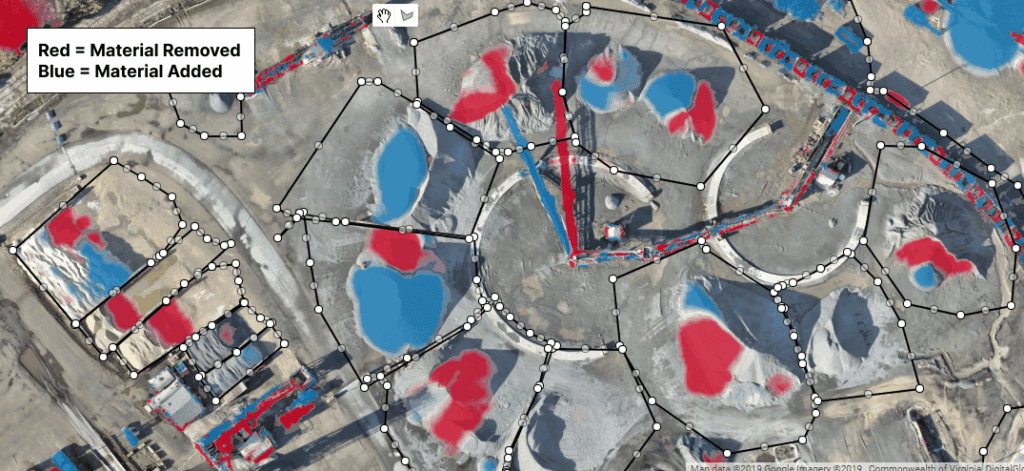

Stockpile Reports solution uses aligned aerials. When you measure a site, the algorithm automatically finds thousands of ground features in the imagery, such as building corners and stationary equipment, and matches them with features from your last flight. By anchoring these features together, your latest site measurement will be perfectly aligned relative to the previous one. You get precision between flights without the expense of setting and maintaining control points.

The result is fast, consistent, and reliable stockpile measurements that don’t slow down your operations.

The Real Factors That Impact Accuracy

If you’re looking for the most accurate stockpile measurement, it’s not GCPs that make the difference. Other ground conditions have a much bigger impact on the reliability of your drone measurements:

- Standing water – Drones can’t see through water. Pools of water around the piles hide the ground surface which can affect the measured ground level.

- Commingled piles – When piles overlap or blend together, the system can’t detect clean boundaries.

- Vegetation – Tall grass and shrubs on and around a pile can obscure the ground level and add volume to the pile.

- Piles against walls – High walls or vertical faces limit how much of the pile surface the drone can capture.

Managing these factors has a far greater effect on measurement quality than whether or not you used GCPs.

The Bottom Line

Ground Control Points are valuable in surveying, but they aren’t necessary for stockpile inventory. What matters most is consistent, repeatable, and precise measurements that reflect the real-world changes in your piles.

Stockpile Reports delivers that through aligned aerials and workflows designed specifically for bulk materials operations. That means you can measure faster, without extra fieldwork, and with confidence in your results. No GCPs required.