August 6, 2020

Instant Measurements: Unlock Incredible Value for Your Business With This Industry-First Tech

7 High-Impact Transformations to Your Business

Stockpile Reports understands the value of your time. Our logistics solutions are designed to be practical and easy-to-use. We constantly push the technology envelope – we want your business to run more smoothly and efficiently, to be more sustainable and economical. Our latest offering – real-time instant measurements – is groundbreaking in that regard. It shaves days, hours, and minutes off the usual stockpiles measurement time, seamlessly and automatically, making it an incredibly potent tool for any business.

SR is the only company in the market offering instant measurements. The capacity to measure in real-time can potentially transform your business:

1.) Make better decisions on where and how to ship material

Transportation is challenging and costly. You need to send supplies from point A to point B in a timely manner to meet customer commitments and contracted service level agreements (SLA) while keeping several factors in mind:

- How much material do you need to send?

- How much material can you actually send?

- Where is this material available?

- Is there enough space at point B?

- Do you have enough trucks?

- How much is it all going to cost?

Measuring the material you have on hand is time-consuming and not always feasible. Operations often rely on out-of-date, stale data and make estimates when transporting, which is inefficient and costly. Mistakes also happen, which either disrupts the supply chain or adds drastically to the cost.

The ability to measure your material stockpiles instantly and know exactly how much you have on hand is a big bonus. With instant measurements, you can make intelligent fact-based transport decisions:

- Know exactly what to send

- Forecast accurately where you have space

- Calculate precisely how much it costs

2.) Make better decisions, period

Instant measurements don’t just facilitate better transport decisions, but better production and business decisions at the whole. With real-time measurements, you can figure out:

- When to stop production

- When to switch to a new material

- When you’re falling short

The ability to control your production precisely offers significant benefits:

- Less time wasted producing material you can’t sell

- Less material sitting on-site and costing you money

- Reduction in the amount of excess/unsold material that you have to re-process

- Reduction in the risk of underproduction and having to switch production back again

- Increased production efficiency from your plants throughout the year

- A reduced average cost per ton for your operations

- Increased confidence in knowing where you stand on production

- Less second-guessing and calls with sales teams

3.) Keep inventory errors way down

Inventory errors are, unfortunately, very common. They’re also expensive. Every operations manager, CFO, or CEO, has dealt with thousands of dollars (or even multi-million dollars) in write-offs at least once in their careers. An ideal write-off rate is +/- 5%. In practice, though, it hovers in the range of +/- 25%. These write-offs are present across all locations, and the total loss can be very significant.

Some types of loss like inventory loss, damage, and theft can’t be prevented. But other types of write-offs – like inventory becoming obsolete and errors arising from miscalculations – can be. With instant measurements, you know exactly how much you need to order and how much you have on hand. You won’t need excess inventory piles and risk them becoming obsolete or damaged. Errors arising from miscalculated conversion rates and estimates can also be minimalized.

4.) Gain the ability to verify deliveries

How many times have you ordered something and then received less than the ordered volume? In some businesses, like construction, it’s a frequent occurrence. This is especially true if you have a cheap but unreliable supplier, which many companies have to use to keep costs down. You end up paying more for less, hurting your bottom line.

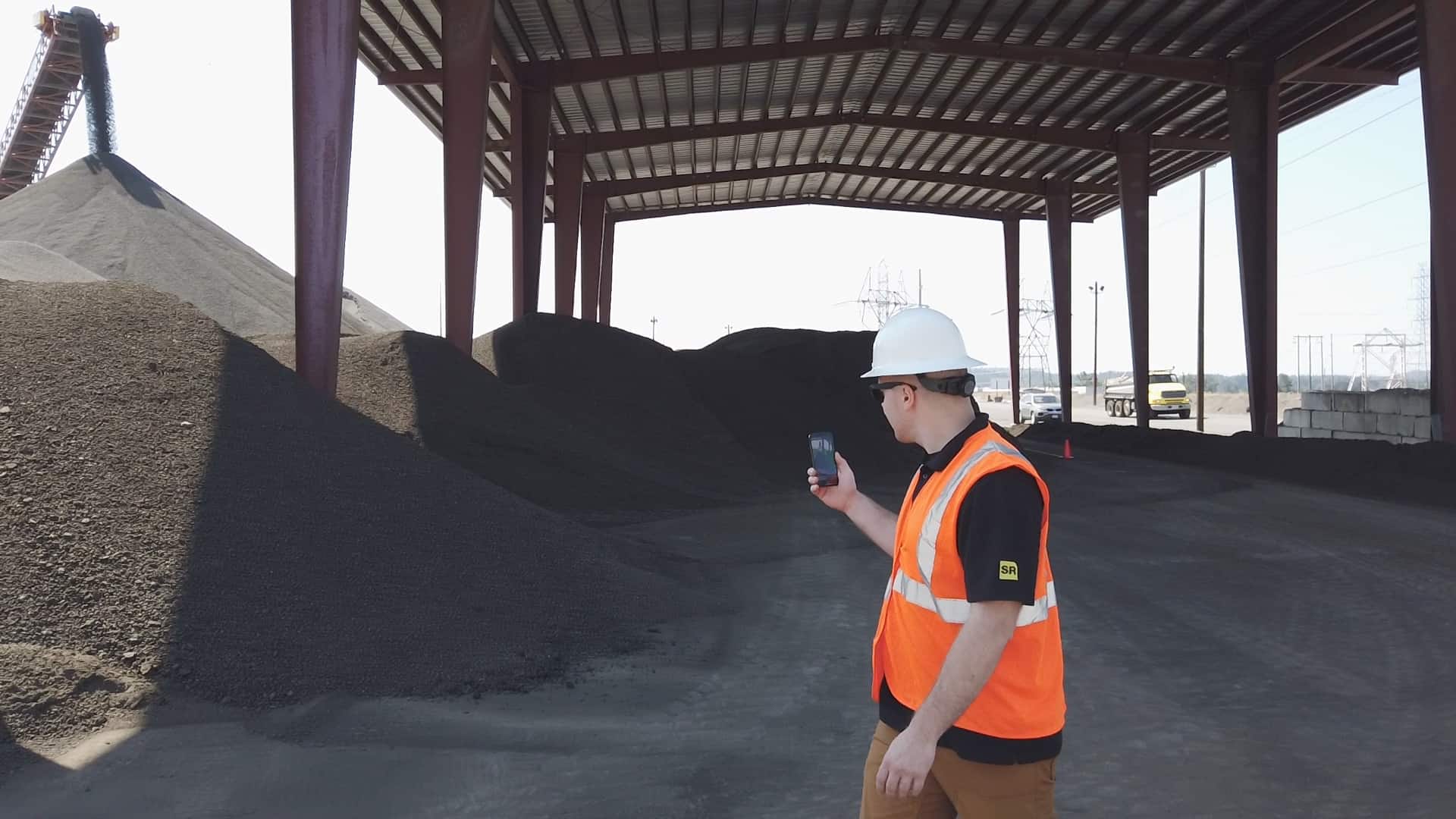

Instant measurements allow you to verify quantities at the time of delivery. That means an employee on-site can validate any incoming delivery simply by walking around the pile with an iPhone. If you’re getting shortchanged, you’ll know – and you’ll be able to prove it. The ability to measure incoming materials instantly offers several other benefits too, such as knowing exactly where you have space to store it.

5.) Manage more flexibly

Instant measurements do more than save time – they also automate your supply chain to a great extent. If you employ our fixed-camera system, you can keep an eye on your stockpiles remotely from anywhere. If an employee on-site has an iPhone, they can use it to measure a stockpile just by scanning it with the camera. It makes managing your stockpiles a hassle-free experience.

For logistics teams, instant measurements allow optimization of order management and fleet operations. Finance teams have to deal with fewer write-offs, leading to more stable finances. Operations receive real-time, actionable data that enables them to make informed decisions. Tight footprint plants are easier to manage, as are high-turn inventories. You can make tons per hour (TPH) adjustments on the fly.

6.) Reduce pressure on employees

Traditional methods of inventory measurement are time-consuming and require expertise. If you do it frequently enough, it requires a significant number of people or a high budget for expensive surveyors. It’s a big commitment. With budget constraints to deal with and operational deadlines to meet, employees are always under pressure. By automating some of their workload – with assistance from drones, fixed cameras, and the iPhone app – you give them extra breathing room. Happy employees are always good for business, not to mention the freed-up time and energy can be put to better use.

7.) Saved resources

Inventory must be measured, that’s a given. The only choice is whether you use traditional methods, with a major reliance on estimates, or new ones that offer reliable data instantly. Traditional methods work, but they are often time-consuming and labor-intensive, which makes them inefficient. Instant measurements require a minimal amount of manpower, are easier to implement, and require less maintenance. It also leads to several tangible benefits – saved time, money, and labor amongst them.

Conclusion

Thanks to instant measurements, you don’t have to rely on out-of-date data anymore, which leads to smoother supply and production chains. Because the plant or other work sites perform better, your bottom-line is healthy. Investors are happier and it’s easier to secure more funding. A better, more efficient business results in more satisfied customers. It’s a constant positive loop that feeds back into your business.

We implemented instant measurements fairly recently and have already received some excellent feedback from our customers. Reach out to us to learn how the power of instant measurements can transform your unique business. If you’re ready to try it for yourself, contact us and let us know you’re interested in our beta program.

Stay In the Know

Be the first to know about the latest Stockpile Reports news and features.